Step into the world of sustainable manufacturing practices where innovation meets eco-consciousness, paving the way for a brighter and cleaner industrial landscape. Get ready to explore how businesses are reshaping their production methods for a sustainable tomorrow.

In today’s fast-paced world, the need for sustainable manufacturing practices has never been more crucial. Let’s delve into the key components and technologies driving this transformative shift in the industry.

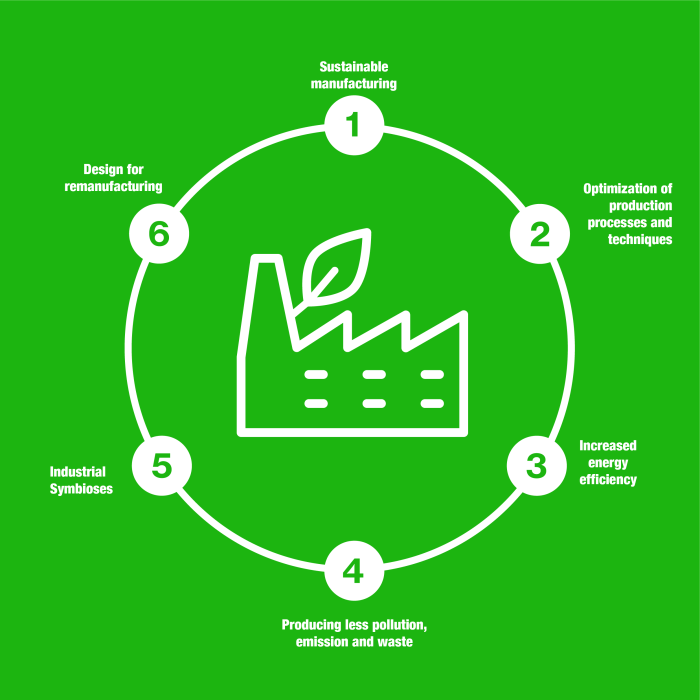

Introduction to Sustainable Manufacturing Practices

Sustainable manufacturing practices refer to the process of producing goods in a way that minimizes negative environmental impacts, conserves energy and natural resources, and ensures the well-being of workers and communities. These practices are essential in today’s industry as they help reduce waste, lower carbon footprint, and promote long-term sustainability.Implementing sustainable practices in manufacturing processes has numerous benefits. Not only does it help companies comply with regulations and meet consumer demand for eco-friendly products, but it also leads to cost savings through increased efficiency and reduced waste.

Additionally, adopting sustainable practices can enhance a company’s reputation, attract environmentally conscious customers, and create a positive impact on society as a whole.Several successful companies have embraced sustainable manufacturing practices as part of their business strategy. For example, Patagonia, a renowned outdoor apparel company, has implemented initiatives to reduce water usage, recycle materials, and promote fair labor practices. Another example is Unilever, a global consumer goods company, which has committed to achieving zero waste to landfill and reducing its environmental footprint through sustainable sourcing and production methods.

Key Components of Sustainable Manufacturing

In sustainable manufacturing, several key components play a crucial role in minimizing environmental impact and promoting a more eco-friendly approach to production. Let’s delve into some of the essential elements that define sustainable manufacturing practices.

Use of Renewable Energy Sources

Renewable energy sources, such as solar, wind, and hydroelectric power, are increasingly being integrated into manufacturing operations to reduce reliance on fossil fuels and lower greenhouse gas emissions. By harnessing these clean energy sources, manufacturers can significantly decrease their carbon footprint and contribute to a more sustainable future for the planet.

Importance of Reducing Waste and Increasing Recycling

One of the fundamental principles of sustainable manufacturing is the reduction of waste generation and the promotion of recycling initiatives. By implementing efficient waste management strategies and recycling programs, manufacturers can minimize the amount of waste sent to landfills, conserve resources, and close the loop on material usage. This not only benefits the environment but also leads to cost savings and improved operational efficiency.

Significance of Eco-Friendly Materials and Products

Using eco-friendly materials and developing sustainable products is another critical aspect of sustainable manufacturing processes. By choosing materials that are biodegradable, recyclable, or made from renewable sources, manufacturers can create products with a lower environmental impact throughout their lifecycle. This shift towards eco-friendly materials not only reduces pollution and resource depletion but also meets the growing consumer demand for sustainable products.

Technologies Driving Sustainable Manufacturing

Advanced technologies play a crucial role in promoting sustainable practices within the manufacturing industry. Let’s explore some of the key technologies driving sustainable manufacturing.

Advanced Automation and Robotics

Automation and robotics have revolutionized the manufacturing sector by streamlining processes, reducing human error, and increasing efficiency. By automating repetitive tasks and optimizing production workflows, manufacturers can minimize energy consumption and waste generation. Additionally, robots are often designed to be energy-efficient and can operate on renewable energy sources, further contributing to sustainability.

Internet of Things (IoT)

The Internet of Things (IoT) refers to the network of interconnected devices that collect and exchange data in real-time. In the context of sustainable manufacturing, IoT technology enables manufacturers to monitor and control energy usage, track resource consumption, and optimize production schedules. By leveraging IoT sensors and data analytics, companies can identify opportunities for energy conservation, reduce operational costs, and improve overall efficiency.

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, offers a sustainable alternative to traditional manufacturing methods. This technology allows manufacturers to create complex designs with minimal material waste, as objects are built layer by layer. By using only the necessary amount of raw materials and reducing energy consumption during production, additive manufacturing significantly lowers the environmental impact of manufacturing processes. Additionally, 3D printing enables on-demand production, reducing the need for excess inventory and transportation emissions.

Sustainable Practices in Industrial Goods and Services

When it comes to sustainable manufacturing practices in the industrial sector, the impact goes beyond just reducing environmental harm. These practices also play a crucial role in enhancing the quality of industrial goods and services, ensuring they meet higher standards of efficiency, durability, and performance.

Impact on Quality of Industrial Goods

Implementing sustainable manufacturing practices can lead to significant improvements in the quality of industrial goods. By optimizing processes and reducing waste, companies can produce products that are more reliable, durable, and of higher quality. This not only benefits the end-users but also enhances the reputation of the company in the market.

Role of Certification Programs

Certification programs play a vital role in verifying sustainable practices in the industrial sector. These programs set standards and guidelines that companies must adhere to in order to be certified as sustainable. By obtaining certifications, companies can demonstrate their commitment to sustainability and build trust with consumers who are increasingly conscious of environmental issues.

Challenges Faced by Industrial Companies

Transitioning to sustainable manufacturing processes is not without its challenges for industrial companies. One major challenge is the initial investment required to upgrade equipment and implement new technologies. Additionally, companies may face resistance from employees who are accustomed to traditional practices and may be resistant to change. Overcoming these challenges requires strong leadership, strategic planning, and a long-term commitment to sustainability.

Conclusion

As we conclude our journey through sustainable manufacturing practices, it’s evident that the future lies in the hands of those who embrace eco-friendly solutions and forward-thinking approaches. Let’s continue to work towards a more sustainable and responsible manufacturing ecosystem.

FAQ Section

How can sustainable manufacturing practices benefit businesses?

Implementing sustainable practices can lead to cost savings, improved brand reputation, and reduced environmental impact, making it a win-win for both businesses and the planet.

What role do renewable energy sources play in sustainable manufacturing?

Renewable energy sources like solar and wind power help reduce carbon emissions and reliance on fossil fuels, promoting a cleaner and greener production process.

How does IoT contribute to energy efficiency in manufacturing?

IoT enables real-time monitoring and optimization of energy usage, allowing manufacturers to identify areas for improvement and enhance overall efficiency in their operations.