Embark on a journey through the fascinating world of robotics in industrial production, where innovation meets efficiency to transform the way we manufacture goods.

From revolutionizing production lines to enhancing workplace safety, robotics play a pivotal role in shaping the future of manufacturing.

Overview of Robotics in Industrial Production

Robotics play a crucial role in modern industrial production, revolutionizing the way goods are manufactured. These automated systems have significantly increased efficiency, accuracy, and productivity in various industries.

Industries Utilizing Robotics

- Automotive: The automotive industry heavily relies on robotics for tasks such as welding, painting, and assembly.

- Electronics: Robotics are used for intricate tasks like soldering, component placement, and testing in electronics manufacturing.

- Food and Beverage: In this sector, robots are employed for packaging, sorting, and even food processing tasks.

- Pharmaceuticals: Robotics play a vital role in pharmaceutical production for precise dispensing, labeling, and packaging of medications.

Benefits of Robotics in Industrial Production

- Increased Efficiency: Robots can work continuously without breaks, leading to faster production cycles and reduced downtime.

- Improved Quality: Automation ensures consistent quality control, reducing errors and defects in the manufacturing process.

- Enhanced Safety: Robots are capable of handling hazardous materials or performing dangerous tasks, keeping human workers out of harm’s way.

- Cost Savings: While the initial investment in robotics may be high, the long-term cost savings from increased productivity and reduced waste make it a worthwhile investment.

Types of Robotics Used in Industrial Production

Robotics play a crucial role in modern industrial production, streamlining processes, increasing efficiency, and ensuring precision. Let’s explore the various types of robots commonly used in industrial settings and how they contribute to production.

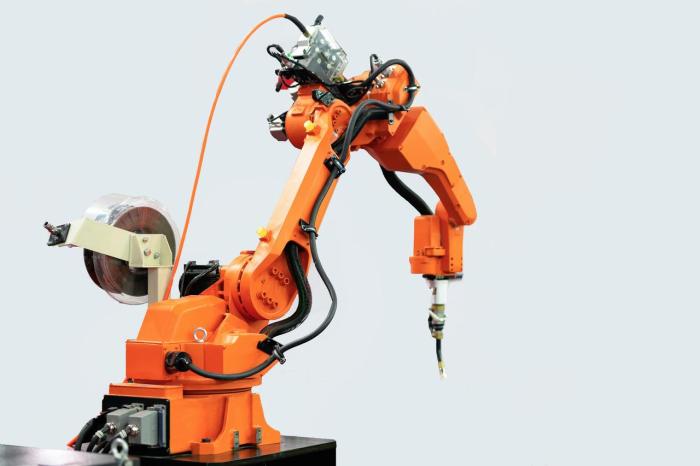

Articulated Robots

Articulated robots are among the most common types used in industrial production. These robots have multiple joints, similar to a human arm, allowing them to move with precision and flexibility. They are typically used for tasks such as welding, painting, and assembly, thanks to their ability to reach into tight spaces and handle complex movements.

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are popular in assembly and material handling tasks. These robots have a horizontal reach and are known for their speed and accuracy. SCARA robots are often used in industries where high-speed, repetitive tasks are required, such as electronics manufacturing.

Delta Robots

Delta robots, also known as parallel robots, are commonly used in industries with high-speed and high-precision requirements, such as packaging and food processing. These robots feature a unique design with three arms connected to a single base, allowing them to move swiftly and accurately in three-dimensional space.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside humans in production settings. These robots have advanced safety features that enable them to operate in close proximity to human workers without the need for safety barriers. Cobots are used for tasks like pick-and-place operations, quality inspection, and machine tending.

Comparing Traditional Industrial Machinery with Robotic Systems

When comparing traditional industrial machinery with robotic systems, it’s evident that robots offer greater performance and flexibility. Traditional machinery is often limited in its capabilities and requires manual operation, leading to inefficiencies and safety risks. In contrast, robotic systems can perform a wide range of tasks with precision, speed, and consistency, enhancing productivity and quality in industrial production.

Benefits of Implementing Robotics in Industrial Production

Integrating robotics in industrial production processes offers a multitude of advantages that can significantly improve efficiency and output.

Cost Reduction and Increased Productivity

- Robotics can perform tasks with precision and consistency, leading to reduced material waste and increased overall production efficiency.

- Automating repetitive tasks through robotics can help in speeding up production processes, resulting in higher productivity levels.

- Robots can operate around the clock without the need for breaks, leading to continuous production cycles and maximizing output.

Enhanced Workplace Safety

- By taking over hazardous tasks, robots help in minimizing the risk of workplace accidents and injuries among human workers.

- Robots are equipped with sensors and safety features that can detect potential dangers and avoid collisions, ensuring a safer working environment.

- Automation of dangerous tasks with robotics reduces the exposure of workers to harmful substances or environments, improving overall workplace safety.

Challenges and Limitations of Robotics in Industrial Production

Robotics in industrial production have revolutionized the manufacturing sector, but they also come with their fair share of challenges and limitations.One of the challenges faced when implementing robotics in industrial production is the high initial investment cost. Setting up a robotic system can be expensive, requiring significant capital expenditure which may not be feasible for all businesses, especially small and medium-sized enterprises.Moreover, the lack of flexibility in current robotic technologies poses a limitation in handling complex production tasks.

Most robots are programmed to perform specific tasks repeatedly and may struggle to adapt to changes in production requirements or environments. This limitation can hinder the efficiency and versatility of robotic systems in industrial settings.To overcome these challenges and limitations, advancements in robotic technologies are needed. For instance, the development of more flexible robots equipped with advanced sensors and artificial intelligence capabilities can enhance adaptability and efficiency in handling complex production tasks.

Additionally, research and innovation in robotic programming and control systems can improve the overall performance and cost-effectiveness of robotics in industrial production.

Enhancing Adaptability and Flexibility

- Integrating machine learning algorithms to enable robots to learn and adjust their operations based on real-time data.

- Implementing collaborative robots (cobots) that can work alongside human operators and adapt to changing production needs.

Improving Programming and Control Systems

- Developing intuitive programming interfaces that allow non-experts to easily program and reconfigure robotic systems.

- Enhancing connectivity and communication protocols to enable seamless integration of robotic systems with other manufacturing technologies.

Future Trends in Robotics for Industrial Production

Robotics in industrial production is constantly evolving, and the future holds exciting new advancements that will shape the way manufacturing processes are carried out. Let’s explore some of the key trends that are expected to revolutionize the field of robotics in industrial production.

Integration of IoT and Robotics

In the future, we can expect to see a greater integration of Internet of Things (IoT) technology with robotics in industrial production. This integration will enable robots to communicate with each other and with other machines on the factory floor, leading to more efficient and seamless production processes.

Collaborative Robotics

Collaborative robots, also known as cobots, are designed to work alongside human workers in a shared workspace. The future of robotics in industrial production will likely see an increase in the use of cobots, as they offer flexibility and versatility in manufacturing environments. These robots can perform tasks that require human-like dexterity and precision, while also ensuring the safety of human workers.

Enhanced Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning are set to play a significant role in the future of robotics in industrial production. These technologies will enable robots to learn from their experiences, adapt to new situations, and make autonomous decisions. This will lead to increased efficiency, productivity, and overall performance in manufacturing processes.

3D Printing and Additive Manufacturing

D printing and additive manufacturing technologies are becoming increasingly popular in industrial production. In the future, we can expect to see robotics being used in conjunction with 3D printing processes to create complex and customized products with greater speed and precision. This integration will revolutionize the way products are manufactured and bring about new possibilities in the field of industrial production.

Autonomous Mobile Robots

Autonomous mobile robots are robots that can navigate and operate in dynamic environments without the need for human intervention. In the future, we can expect to see an increase in the use of these robots in industrial production settings, as they offer flexibility and scalability in carrying out various tasks such as material handling, inventory management, and order fulfillment.

Conclusion

The future of robotics in industrial production is promising, with advancements in technology paving the way for more efficient, flexible, and autonomous manufacturing processes. By embracing these future trends, manufacturers can stay ahead of the curve and unlock new opportunities for growth and innovation in the field of industrial production.

INDUSTRIAL GOODS AND SERVICES

Industrial goods and services play a crucial role in supporting the development and maintenance of robotic systems in industrial production. These components and equipment are essential for ensuring the smooth operation and efficiency of robotic applications.

Components Provided by Industrial Goods and Services

Industrial goods and services companies provide a wide range of components that are essential for robotic applications. These include precision sensors, actuators, grippers, motors, controllers, and vision systems. These components are carefully designed and manufactured to meet the specific requirements of robotic systems, ensuring optimal performance and reliability.

- Precision Sensors: These sensors play a critical role in detecting and measuring various parameters in the robotic environment, allowing robots to interact with their surroundings accurately.

- Actuators: Actuators are responsible for converting energy into mechanical motion, enabling robots to move and perform various tasks with precision.

- Grippers: Grippers are essential for robots to pick up and manipulate objects in industrial settings, ensuring efficient handling and processing of materials.

- Motors: Motors provide the necessary power to drive the movement of robotic systems, allowing them to perform tasks quickly and accurately.

- Controllers: Controllers are the brains of robotic systems, responsible for coordinating and controlling the actions of various components to achieve the desired outcomes.

- Vision Systems: Vision systems use cameras and image processing algorithms to provide robots with the ability to see and recognize objects, enabling them to navigate and interact with their environment effectively.

Collaboration between Industrial Goods and Services Manufacturers and Robotics Companies

Manufacturers of industrial goods and services often collaborate closely with robotics companies to drive innovation in industrial production. By working together, these companies can combine their expertise and resources to develop advanced solutions that meet the evolving needs of the industry.

Collaboration between industrial goods and services manufacturers and robotics companies is essential for pushing the boundaries of technology and enhancing the capabilities of robotic systems in industrial production.

End of Discussion

As we delve deeper into the realm of robotics in industrial production, it becomes evident that this technological advancement is not just a trend but a fundamental shift in how we approach manufacturing processes.

FAQ Explained

Are robots only used in large industries?

No, robots are increasingly being adopted by small and medium-sized industries to improve efficiency and productivity.

Can robots completely replace human workers in industrial production?

While robots can automate many tasks, human workers are still essential for more complex decision-making and tasks that require creativity.

Do robots in industrial production require constant maintenance?

Yes, regular maintenance is crucial to ensure optimal performance and longevity of robotic systems in industrial settings.