Industrial automation trends 2025 sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with entertaining interactive style and brimming with originality from the outset.

Get ready to dive into a world where technology and automation converge to shape the future of industries, paving the way for a new era of efficiency and innovation.

Industrial Automation Trends 2025

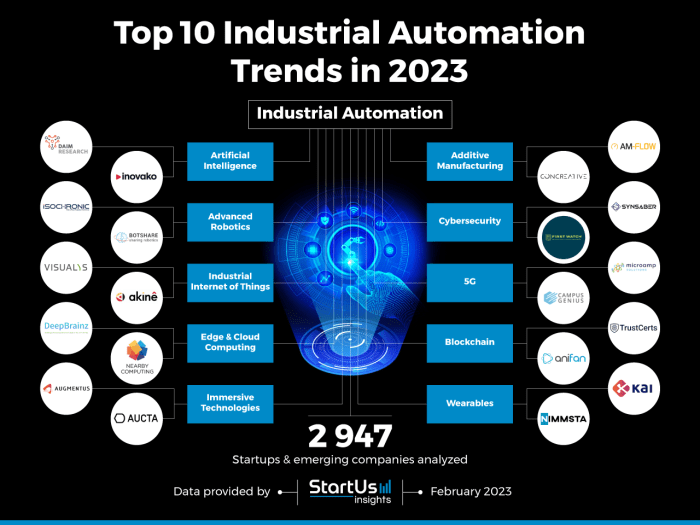

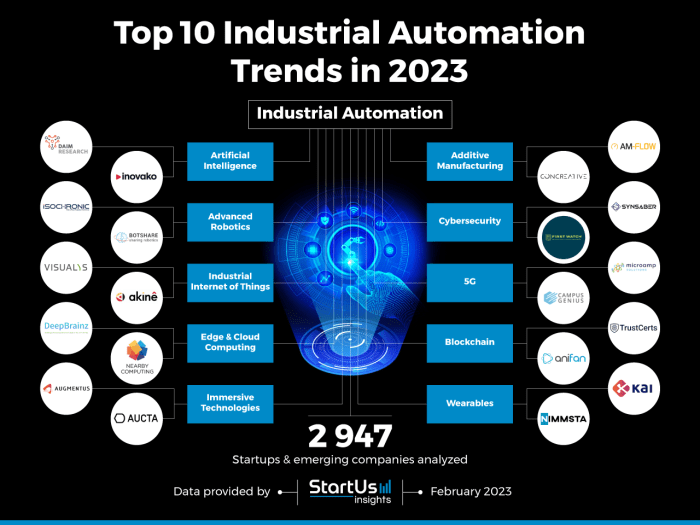

The year 2025 is expected to witness significant advancements in industrial automation, driven by key technologies such as artificial intelligence, machine learning, and the Industrial Internet of Things (IIoT). These technologies are set to revolutionize the way industries operate and increase efficiency.

Key Technologies Driving Industrial Automation Trends

- Robotics: The integration of advanced robotics in industrial processes will enhance productivity and precision, leading to streamlined operations.

- Artificial Intelligence (AI): AI algorithms will enable machines to learn from data, make decisions, and perform tasks with minimal human intervention.

- Machine Learning: Machine learning algorithms will allow systems to improve performance over time by analyzing patterns and making predictions based on data.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies will provide immersive experiences for training, maintenance, and troubleshooting in industrial settings.

Impact of Artificial Intelligence and Machine Learning

- Efficiency Boost: AI and machine learning will optimize production processes, reduce downtime, and enhance overall efficiency in industrial operations.

- Predictive Maintenance: Predictive maintenance powered by AI algorithms will help anticipate equipment failures before they occur, minimizing costly downtimes.

- Smart Decision-Making: AI-driven analytics will enable real-time data analysis, leading to informed decision-making and proactive responses to changing conditions.

Role of Industrial Internet of Things (IIoT)

- Connected Ecosystem: IIoT will create a connected ecosystem where devices, machines, and systems can communicate and collaborate seamlessly.

- Data-driven Insights: IIoT sensors will collect and analyze data to provide valuable insights for optimizing processes, improving quality, and reducing waste.

- Remote Monitoring and Control: IIoT will enable remote monitoring and control of industrial equipment, enhancing operational efficiency and safety.

Future of Robotics in Industrial Automation

Robotic technology is set to revolutionize the landscape of industrial automation by 2025, bringing about significant advancements in efficiency, productivity, and safety within manufacturing processes.

Advancements in Robotics by 2025

- Enhanced AI and machine learning capabilities in robots to optimize decision-making and adaptability in dynamic environments.

- Integration of advanced sensors and vision systems for improved precision and accuracy in tasks such as pick-and-place operations.

- Development of modular and customizable robotic systems to facilitate easy reconfiguration and scalability in production lines.

- Implementation of predictive maintenance algorithms to minimize downtime and enhance overall equipment effectiveness.

Collaborative Robots (Cobots) in Manufacturing Processes

Collaborative robots, or cobots, are expected to play a crucial role in the manufacturing industry by 2025. These robots are designed to work alongside human operators, enhancing productivity and efficiency while ensuring safety in shared workspaces.

- Integration of cobots in assembly lines to assist workers with repetitive tasks, leading to increased throughput and reduced ergonomic strain.

- Utilization of cobots for quality control and inspection processes to enhance accuracy and consistency in product output.

- Implementation of smart cobots equipped with sensors and AI algorithms for real-time decision-making and adaptive behavior in response to changing production requirements.

Autonomous Mobile Robots (AMRs) in Industrial Settings

Autonomous mobile robots, or AMRs, are poised to transform the logistics and warehousing sector in industrial settings by 2025. These robots are capable of navigating complex environments without external guidance, revolutionizing material handling operations.

- Deployment of AMRs for goods transportation within warehouses and distribution centers, optimizing workflow efficiency and minimizing human intervention.

- Utilization of AMRs for inventory management and replenishment tasks, enabling real-time tracking and updating of stock levels with precision and speed.

- Integration of fleet management systems to coordinate multiple AMRs for seamless collaboration and task allocation, enhancing overall operational productivity.

Sustainable Practices in Industrial Automation

In the realm of industrial automation, sustainability has become a key focus for companies looking to reduce their environmental impact and improve operational efficiency. By embracing green technologies and renewable energy sources, businesses can not only lower their carbon footprint but also benefit from cost savings and increased productivity.

Influence of Green Technologies

Green technologies, such as energy-efficient machinery and smart sensors, are expected to revolutionize industrial automation trends by 2025. These technologies will enable companies to monitor and optimize their energy usage, leading to reduced waste and lower operating costs.

Adoption of Renewable Energy Sources

More and more automated industrial processes are shifting towards renewable energy sources like solar and wind power. By harnessing clean energy, companies can decrease their reliance on fossil fuels, mitigate climate change impacts, and create a more sustainable future for the manufacturing sector.

Importance of Energy-Efficient Automation Solutions

Energy-efficient automation solutions play a crucial role in promoting sustainability in manufacturing. By implementing smart systems that consume less energy and optimize resource utilization, companies can achieve higher productivity levels while minimizing their environmental footprint. This not only benefits the planet but also enhances the reputation of businesses as socially responsible entities.

Human-Machine Collaboration

In the realm of industrial automation, the collaboration between humans and machines is becoming increasingly crucial. As automation technologies continue to advance, the role of humans is evolving to work alongside machines in a more integrated manner. This shift brings about the need for upskilling and reskilling the workforce to adapt to these new automated processes.

Augmented Reality and Virtual Reality Impact

Augmented reality (AR) and virtual reality (VR) are revolutionizing human-machine collaboration in manufacturing. AR and VR technologies provide immersive experiences that allow workers to interact with machines in a virtual environment. This not only enhances training processes but also improves overall efficiency and safety in industrial settings.

Importance of Upskilling and Reskilling

As automation takes over routine tasks in manufacturing, the workforce needs to acquire new skills to operate and maintain these automated systems. Upskilling and reskilling programs are essential to ensure that employees are equipped to work alongside machines effectively. This investment in training not only benefits the individual workers but also contributes to the overall productivity and competitiveness of the industry.

Industrial Goods and Services

In the world of industrial automation, the availability of innovative products and services plays a crucial role in enhancing efficiency, productivity, and competitiveness for businesses across various industries. Let’s delve into some examples of cutting-edge industrial automation products and the latest services offered by leading companies.

Innovative Industrial Automation Products

- Collaborative Robots (Cobots): These robots are designed to work alongside human workers, enhancing productivity and safety in manufacturing environments.

- Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles that can transport materials within a facility, optimizing logistics and streamlining operations.

- Smart Sensors and IoT Devices: These devices enable real-time monitoring and data collection, allowing for predictive maintenance and improved decision-making.

Latest Industrial Automation Services

- Remote Monitoring and Diagnostics: Companies now offer remote monitoring services to track equipment performance and address maintenance issues proactively.

- Integration Solutions: Service providers offer seamless integration of automation systems with existing infrastructure, ensuring smooth operation and minimal downtime.

- Training and Support: Leading companies provide comprehensive training programs and ongoing support to help businesses maximize the benefits of automation technologies.

Customization Options for Industrial Automation Solutions

- Industry-Specific Solutions: Companies offer tailored automation solutions designed to meet the unique requirements of different industries such as automotive, aerospace, pharmaceuticals, and more.

- Modular Systems: Modular automation systems allow for flexibility and scalability, enabling businesses to customize their solutions based on evolving needs and technological advancements.

- Consultation and Design Services: Service providers collaborate with businesses to design bespoke automation solutions that align with their goals, budget, and operational requirements.

Last Point

As we close the curtains on this exploration of industrial automation trends 2025, it’s evident that the future holds immense potential for transformative changes in how we approach manufacturing and production processes. The stage is set for a thrilling journey ahead, where humans and machines collaborate to redefine the landscape of automation.

Questions Often Asked

What are the key technologies driving industrial automation trends in 2025?

Key technologies include artificial intelligence, machine learning, and the Industrial Internet of Things (IIoT).

How will green technologies influence industrial automation trends by 2025?

Green technologies will play a significant role in promoting sustainability and energy efficiency in automated industrial processes.

What is the potential of autonomous mobile robots (AMRs) in industrial settings in the next few years?

AMRs have the potential to revolutionize industrial settings by offering autonomous and flexible solutions for various tasks.