Step into the world of industrial energy efficiency solutions where cutting-edge technologies and innovative strategies converge to revolutionize energy consumption in manufacturing processes. Get ready for a journey filled with insights and practical tips to optimize energy usage like never before!

Industrial Energy Efficiency Solutions

Industrial energy efficiency solutions refer to the strategies and technologies implemented in manufacturing processes to reduce energy consumption and optimize resource utilization.Implementing energy-efficient practices in industrial settings is crucial for several reasons. First and foremost, it helps companies reduce their operational costs by lowering energy bills and improving overall efficiency. Additionally, it contributes to environmental sustainability by reducing greenhouse gas emissions and minimizing the carbon footprint of industrial activities.

The Benefits of Using Technology in Industrial Energy Efficiency

Using technology to optimize energy consumption in industries offers numerous advantages. Some of the key benefits include:

- Real-time monitoring and control of energy usage, allowing for immediate adjustments to optimize efficiency.

- Integration of smart sensors and automation systems to identify energy waste and implement energy-saving measures.

- Implementation of energy management software for data analysis and performance tracking to identify areas for improvement.

- Utilization of energy-efficient equipment and machinery to reduce energy consumption without compromising productivity.

Strategies for Improving Industrial Energy Efficiency

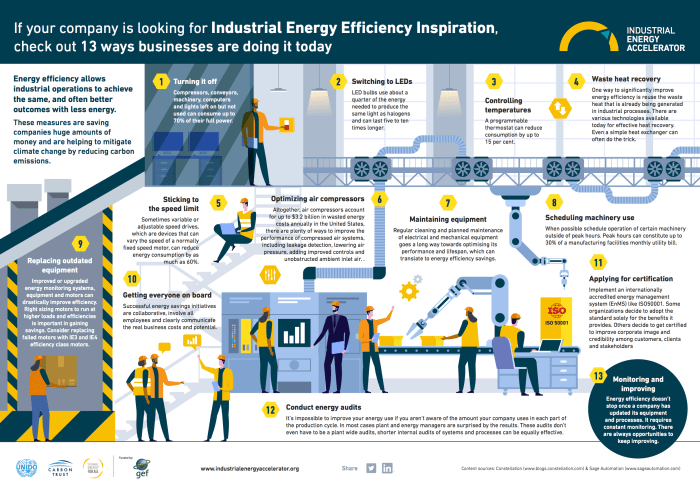

Industrial energy efficiency can be significantly improved through various strategies, including energy audits, retro-commissioning, process optimization, and the integration of renewable energy sources. By implementing these strategies, industrial facilities can reduce energy waste, lower operational costs, and minimize their environmental impact.

Energy Audits and Retro-Commissioning

Energy audits involve a comprehensive assessment of energy consumption in an industrial facility to identify areas of inefficiency and potential savings opportunities. Retro-commissioning, on the other hand, focuses on optimizing existing building systems and equipment to improve energy performance. By conducting regular energy audits and retro-commissioning activities, industrial facilities can identify and address energy inefficiencies, leading to significant cost savings and improved overall energy efficiency.

Process Optimization

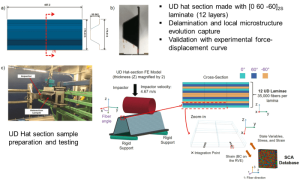

Process optimization plays a crucial role in improving industrial energy efficiency by optimizing production processes to minimize energy consumption. This can involve implementing advanced control systems, upgrading equipment, and fine-tuning operational procedures to maximize energy efficiency. By optimizing production processes, industrial facilities can reduce energy waste, improve productivity, and enhance overall operational efficiency.

Renewable Energy Sources

Integrating renewable energy sources, such as solar, wind, and biomass, can further enhance industrial energy efficiency by reducing dependence on traditional fossil fuels and lowering greenhouse gas emissions. By harnessing renewable energy sources, industrial facilities can generate clean and sustainable power to meet their energy needs. Additionally, incorporating renewable energy technologies can help diversify energy sources, improve energy resilience, and contribute to a more sustainable future.

Technologies for Industrial Energy Efficiency

Industrial energy efficiency can be greatly enhanced through the adoption of various technologies that help in monitoring, managing, and optimizing energy usage in factories. Key technologies like smart meters, energy management systems, IoT devices, sensors, AI, and machine learning play a crucial role in improving energy efficiency and reducing operational costs.

Smart Meters and Energy Management Systems

Smart meters are advanced energy measurement devices that provide real-time data on energy consumption, allowing companies to track and analyze their energy usage patterns. Energy management systems, on the other hand, help in monitoring, controlling, and optimizing energy consumption within industrial facilities. By integrating smart meters and energy management systems, businesses can identify areas of energy wastage and implement strategies to reduce energy consumption.

Impact of IoT Devices and Sensors

IoT devices and sensors play a vital role in monitoring energy usage in factories by collecting data on equipment performance, temperature, humidity, and other relevant parameters. This real-time data enables businesses to identify inefficiencies, predict maintenance needs, and optimize energy-intensive processes. By leveraging IoT devices and sensors, companies can achieve significant energy savings and improve overall operational efficiency.

Integration of AI and Machine Learning

The integration of AI and machine learning technologies in industrial processes can help optimize energy-intensive operations by analyzing vast amounts of data and identifying patterns that human operators may overlook. AI algorithms can optimize energy consumption in real-time, predict equipment failures, and recommend energy-saving measures. By harnessing the power of AI and machine learning, businesses can achieve higher levels of energy efficiency and reduce their carbon footprint.

Case Studies on Successful Industrial Energy Efficiency Projects

In this section, we will explore real-life examples of industries that have successfully reduced energy consumption through implementing energy-efficient solutions. These case studies will highlight the outcomes achieved in terms of cost savings and environmental benefits.

Automotive Manufacturing Plant

- An automotive manufacturing plant in the Midwest implemented energy-efficient lighting systems and upgraded their HVAC systems.

- The plant saw a 20% reduction in energy consumption within the first year of implementing these changes.

- This led to annual cost savings of over $200,000 and a significant decrease in carbon emissions.

Food Processing Facility

- A food processing facility in California invested in energy-efficient machinery and optimized their production processes.

- By reducing energy waste and implementing smart controls, the facility decreased its energy consumption by 15%.

- This resulted in annual savings of $150,000 and a notable reduction in their overall environmental impact.

Steel Manufacturing Plant

- A steel manufacturing plant in the Northeast upgraded their equipment and implemented a comprehensive energy management system.

- Through improved energy monitoring and efficiency measures, the plant achieved a 25% reduction in energy usage.

- This translated to yearly cost savings of over $300,000 and a substantial decrease in greenhouse gas emissions.

Industrial Goods and Services

In the industrial sector, the role of suppliers in providing energy-efficient equipment is crucial for helping industries reduce their energy consumption and costs. By offering innovative technologies and solutions, suppliers play a vital role in supporting industrial energy efficiency initiatives.

Suppliers Providing Energy-Efficient Equipment

- Suppliers work closely with industries to understand their specific needs and challenges, providing customized solutions to improve energy efficiency.

- They offer a wide range of energy-efficient equipment, such as high-efficiency motors, variable frequency drives, and LED lighting systems, to help industries optimize their energy usage.

- By partnering with reputable suppliers, industries can access cutting-edge technologies that can significantly reduce energy consumption and greenhouse gas emissions.

Importance of Maintenance Services for Industrial Machinery

- Regular maintenance of industrial machinery is essential to ensure optimal performance and energy efficiency.

- Proper maintenance helps identify and address issues that may lead to energy wastage, such as leaks, worn-out components, or inefficient operation.

- By investing in maintenance services, industries can prolong the lifespan of their equipment, reduce downtime, and enhance overall energy efficiency.

Consulting Firms Supporting Sustainable Practices

- Consulting firms play a critical role in helping businesses adopt sustainable practices for energy conservation.

- They provide expert guidance and strategic advice to industries on implementing energy-efficient solutions and reducing their environmental impact.

- Through energy audits, performance benchmarking, and sustainability assessments, consulting firms help businesses identify opportunities for improvement and develop tailored strategies for energy conservation.

Closing Notes

As we conclude this enlightening discussion on industrial energy efficiency solutions, remember that by embracing energy-efficient practices and leveraging advanced technologies, industries can pave the way towards a sustainable future while reaping the benefits of cost savings and environmental conservation. It’s time to power up with efficiency!

Answers to Common Questions

How can industrial energy efficiency solutions benefit manufacturing processes?

Implementing energy-efficient practices can lead to reduced operational costs, increased productivity, and a smaller environmental footprint.

What are some common strategies for improving industrial energy efficiency?

Energy audits, retro-commissioning, and process optimization are key strategies used to enhance energy efficiency in industrial settings.

How do smart meters and energy management systems contribute to industrial energy efficiency?

Smart meters and energy management systems help monitor and optimize energy consumption, leading to more efficient operations and cost savings.

Why is the integration of AI and machine learning important for optimizing energy-intensive processes?

AI and machine learning technologies can analyze data patterns and optimize energy usage in real-time, resulting in significant energy savings and operational efficiencies.

How do suppliers and maintenance services play a role in industrial energy efficiency?

Suppliers provide energy-efficient equipment, while maintenance services ensure that machinery operates at peak efficiency, contributing to overall energy conservation.